GUIDE TO COATINGS ON KNITTED GLOVES

The birth of the modern working glove began in the 1970s when labour laws were introduced and occupational safety and health administrations formed to enforce them. Safety gloves are now primarily focused on occupational safety, protecting hands from specific mechanical risks with different features.

The 1980s saw the introduction of knitted safety gloves that offered new features such as stretchable liners with a seamless shell that conforms to the hands for an exact fit and exceptional comfort.

Adding a coating to the knitted gloves opens up more possibilities, offering specific protection for different industries. Therefore, identifying the right type of coating for the job is essential.

- 1. Coating Materials

- 2. Coating Styles

- 3. Coating Layers

1. Coating materials

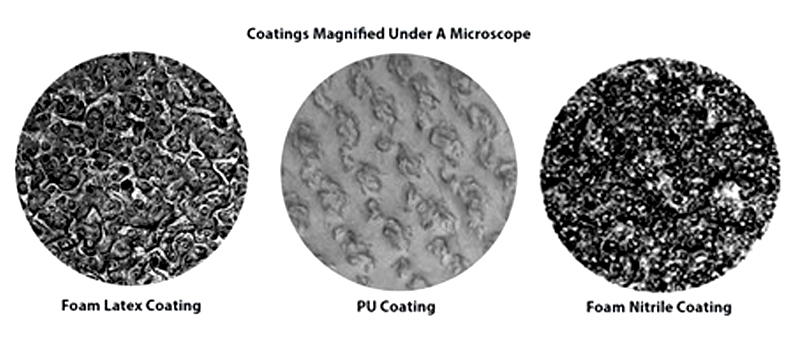

The most common coatings available in the market are Nitrile, Latex and PU (polyurethane).

Nitrile Coating

Nitrile coating is the most popular and common material used to coat working gloves. Nitrile is inherently puncture, abrasion, and chemical resistant. This material can be further divided into two types of coatings:

Smooth Nitrile

This type of palm coating has a smooth finished surface. It offers excellent resistance to abrasion, puncture, and tearing. It holds up well in wet & oily conditions and is performing exceptionally in dry conditions. It also withstands a wide range of temperatures. Smooth nitrile-coated gloves work best in general work that requires high dexterity, such as handling electronic components, assembly, carpentry, and similar light/medium industry.

Micro-foam nitrile

More info on the glove above: Hanvo® Bestgrip Breathtech (HV-NJ506)

Micro-foam nitrile coated glove uses a chemical or water-based treatment to create small pores on the surface. The spongy palm texture enhances the wearing experience. It can also absorb liquids and offers a much better grip than smooth nitrile. However, foam nitrile's open pore structure can become saturated when subjected to excessive oil and wet conditions. In this case, it is best performing in dry and light oily/wet conditions. Micro-foam nitrile glove is suitable for construction, fabrication, lightly oily environments.

Micro-foam Nitrile, enhanced with Sandy Grip finish

More info on the glove above: Hanvo® Bestgrip Blackiro (HV-NXC3158)

The enhancement of the micro-foam nitrile with sandy grip finish offers an improved grip on all surfaces. It is a considerable barrier to liquid permeation. Sandy nitrile's texture is created by using a sandy etching to create small bumps and ridges for better grip in oily conditions.

Latex Coating

Latex is also known as natural rubber and is the only natural material used on working gloves. Although not suitable for people sensitive to latex proteins, it is still a popular choice for its high elasticity and extremely firm grip, even on wet surfaces. Latex is high in tear & puncture resistance and can withstand high temperatures, and they are incredibly durable. Latex resists alcohols but is less suitable for organic solvents like gasoline. There are three common latex coatings in the market:

Smooth latex

More info on the glove above: Rubberex® Multi Purpose (RX-RF1Y)

Smooth latex has a flat, clean surface that keeps liquid away from the hands while maintaining a good grip in both wet and dry conditions, offering good abrasion resistance and remain flexible and durable in all temperatures.

Smooth latex with Sandy Grip finish

More info on the glove above: Hanvo® Bestgrip Aquaguard Hyperguard (HV-LKX3150)

Working gloves with sandy grip treatment on the palm surface give a better grip on all surfaces. When the rough sandy texture on the palm interacts with the surface area, it results in more friction. Therefore, it works better in slippery but non-oily conditions.

Micro-foam latex, enhanced with Sandy Grip finish

More info on the glove above: Hanvo® Bestgrip W-Soldier (HV-LXC2153)

Micro-foam latex with sandy grip finished offers a great wearing experience with the palm's spongy feeling. The rugged finish gives exceptional grip in dry and wet conditions. Micro-foamed latex coated gloves are considered the most liquid-proof gloves as long as it is not oily liquids.

Crinkled Latex

Crinkled latex coated glove shares the same properties as foam latex. The coating is designed to enhance the abrasion level further and strengthen the grip in dry & wet conditions. The crinkled feature does not affect the flexibility but makes the glove slightly thicker. It is more suitable for heavy-duty work, which demands less dexterity. This type of gloves is ideal for glass manufacturing, steel erecting, construction work, and other medium and heavy industry.

PU coating (Polyurethane)

More info on the glove above: Hanvo® Bestgrip Stretch Zero (HV-PE802)

Polyurethane, also known as PU, is the lightest, thinnest and softest options for glove coating, although it is only available in smooth coating. It offers exceptional tactile sensitivity while maintaining a respectable level of abrasion resistance. In general, PU coated gloves are very breathable making them comfortable to wear, especially during summertime. It has the most outstanding grip level among all the coatings in dry condition but not as great in wet and oily conditions. PU is considered a cost-effective solution for general and assembly work with a good level of hand protection. It is suitable for aerospace, appliance manufacturing, or any industries where precision is a requirement.

Solvent-based PU

Most PU gloves are made by dissolving polyurethane in a solvent known as dimethylformamide – or DMF, for short. The glove liners are dipped into the mixture of polyurethane and DMF, soaked in a hot water bath, and cured in an oven. Although virtually all DMF is removed in the hot water bath or evaporates in the oven, trace amounts of DMF are still present in many polyurethane coated gloves.

Water-based PU

Water-based PU gloves replace the solvent dimethylformamide (DMF) with water. As a result, water-based PU gloves eliminate the risk of an allergic reaction for sensitive wearers. It shares the same feature and benefit as solvent-based PU while manufactured in a more environmentally friendly way. Water-based PU also offers better dirt repellence compared with solvent-based PU.

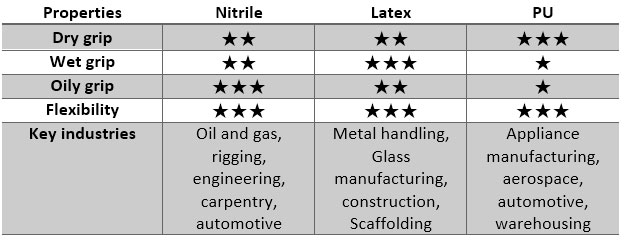

Glove coating materials summary

The table above is just a general reference for typical coated gloves. It is recommended to refer to the specification of the glove model and compare it to the company risk analysis when choosing gloves.

2. Coating style

Glove coatings are available in several different styles covering different portions of the hand. Here is a summary of what is available:

More info on the glove above: Hanvo® Bestgrip Breathtech Lite (HV-NJ81110)

Palm coated

The coated area covers the entire palm and tips of fingers. This coating style focuses mainly on the palm and fingertip protection while maintaining superior ventilation. This is the most common type of coating style.

More info on the glove above: Soft Touch® ErgoTec© (ADF-870)

Half coated

The coating is covering the entire palm, fingers, and knuckles. This coating style provides coverage for the essential part of the hands from various hazards while still support decent ventilation. This coating style also provides additional protection to liquids.

More info on the glove above: Hanvo® Bestgrip Aquaguard (HV-LKX301)

Fully coated

The coated area covers the entire hand up to the lower wrist. This coating style support complete protection of the hand and give the highest liquid protection. It also has insulating properties as heat from the hands are maintained inside the glove. The glove also becomes waterproof with this type of coating.

Finger coated

The coating material is only covering the fingertips. This supports maximum flexibility and breathability of the glove while still maintaining a great grip on just the fingertips. Suitable for handling small objects like in the electronics industry.

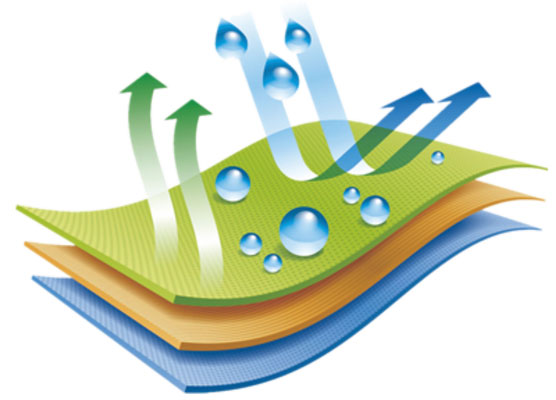

3. Coating Layer

More info on the glove above: Hanvo® Bestgrip Hyperguard (HV-NXC3157)

A single layer coating is the most common version on the market. In most cases, this provides adequate protection, but new technology has emerged that improve the glove coating by adding additional protective layers.

It may sound simple, but the trick is to meet a balance of the glove’s performance and lifespan while maintaining flexibility, tactile sensitivity and comfort.

More info on the glove above: Hanvo® Bestgrip Safaith Thermo (HV-LKX680)

Double coated

Double coating is becoming more commonly available in the market. A glove with an additional layer of coating improves durability, water and oil resistance, and abrasion resistance. It also has the advantage of being waterproof.

More info on the glove above: Hanvo® Bestgrip Aquaguard Thermo (HV-LKX970)

Triple coated

With three layers of coating on the glove hand protection is greatly enhanced. The abrasion resistance becomes outstanding as well as the durability which extends the life of the glove. Only a handful of models are available in the market with this feature since the technology is still relatively new.

More info on the glove above: Hanvo® Bestgrip Breathtech plus (HV-NR506)

Raised dots

Some coated gloves come with an additional layer of raised dot. It is treated as an enhanced layer of protection on the palm for extra durability, dampening, and abrasion resistance.

Take care of your hands

You have only one pair of hands, and our goal is that you keep them safe. We hope that this guide has provided you with guidance for choosing the correct glove for the job.

Stay safe with us.

For inquiries and questions

If you have any questions, don't hesitate to contact us via e-mail: (Contact information) or social media: Facebook or LinkedIn.